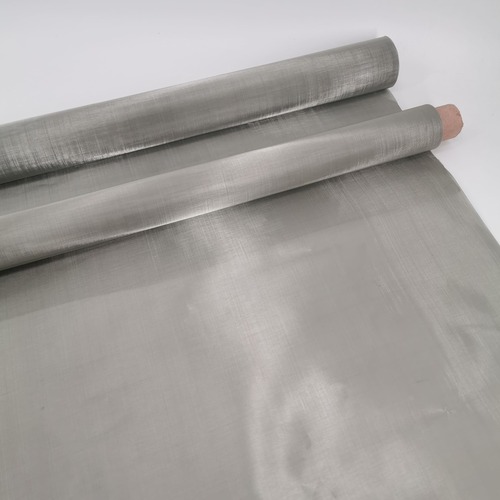

304 Stainless Steel Wire

304 stainless steel wire is a general purpose stainless alloy typically composed of 18% chromium and 8% nickel. It is the most widely used stainless spring wire because of its high corrosion resistance properties and good tensile strength

304 stainless steel wire is a general purpose stainless alloy typically composed of 18% chromium and 8% nickel.

It is the most widely used stainless spring wire because of its high corrosion resistance properties and good tensile strength.

For spring applications it is generally furnished in the cold drawn condition. Type 304 springs have good strength at moderate temperatures.

If properly treated after forming they will set less than most other spring materials at temperatures up to 500ºF.

Type 304 material in the spring condition is slightly magnetic due to the transformation of some martinsite in the drawing operation.

The greater the amount of cold reduction the higher the degree of magnetism.

Smart Craftsmen soap coated Type 304 stainless steel wire is available in the size range 0.014" to 0.625".

-Elemental composition is more stable;

-Better in corrosion resistance and high temperature proof,suitable for strong corrosive and high temperature environment;

-Steel ring quality:the surface of the product is smooth without cracks,safe to use;

-The products strictly use standard raw materials,and strictly control the product quality during the production process.

Supplying Size

Diameter 0.1 to 15 mm ; 0.005 to 0.6 inch

Delivery condition

Types 304 shall be cold drawn to produce the required mechanical properties.

| Composition, % | ||||||||

| Type | C, ≤ | Si, ≤ | Mn, ≤ | P, ≤ | S, ≤ | Cr | Ni | N, ≤ |

| 304L | 0.03 | 1 | 2 | 0.045 | 0.03 | 18.00-20.00 | 8.00-10.50 | 0.1 |

| 304 Soft Wires | |||||

| 304 Hard Wires | |||||

| Ø | Tolerance | Ovality | Tensile Strength | Tensile Strength | Elongation |

| (mm) | (mm) | (mm) | (kgf / mm2) | (N / mm2) | (%) |

| 0.03 | ± 0.003 | 0.003 | 70 - 100 | 686 - 980 | 10 min |

| 0.04 | |||||

| 0.05 | ± 0.004 | 0.004 | |||

| 0.06 | 70 - 90 | 686 - 882 | 20 min | ||

| 0.07 | |||||

| 0.08 | |||||

| 0.09 | ± 0.005 | 0.005 | |||

| 0.1 | |||||

| 0.12 | ± 0.007 | 0.007 | |||

| 0.14 | |||||

| 0.16 | |||||

| 0.18 | ± 0.010 | 0.01 | 70 - 85 | 686 - 833 | |

| 0.2 | |||||

| 0.25 | |||||

| 0.3 | |||||

| 0.35 | ± 0.013 | ||||

| 0.4 | |||||

| 0.45 | |||||

| 0.5 | |||||

| 0.55 | ± 0.015 | 0.015 | 65 - 85 | 637 - 833 | 30 min |

| 0.6 | |||||

| 0.65 | |||||

| 0.7 | |||||

| 0.75 | |||||

| 0.8 | |||||

| 316 Soft Wires | |||||

| 316 Hard Wires | |||||

| Ø | Tolerance | Ovality | Tensile Strength | Tensile Strength | Elongation |

| (mm) | (mm) | (mm) | (kgf / mm2) | (N / mm2) | (%) |

| 0.03 | ± 0.003 | 0.003 | 70 - 100 | 686 - 980 | 10 min |

| 0.04 | |||||

| 0.05 | ± 0.004 | 0.004 | |||

| 0.06 | 70 - 90 | 686 - 882 | 20 min | ||

| 0.07 | |||||

| 0.08 | |||||

| 0.09 | ± 0.005 | 0.005 | |||

| 0.1 | |||||

| 0.12 | ± 0.007 | 0.007 | |||

| 0.14 | |||||

| 0.16 | |||||

| 0.18 | ± 0.010 | 0.01 | 70 - 85 | 686 - 833 | |

| 0.2 | |||||

| 0.25 | |||||

| 0.3 | |||||

| 0.35 | ± 0.013 | ||||

| 0.4 | |||||

| 0.45 | |||||

| 0.5 | |||||

| 0.55 | ± 0.015 | 0.015 | 65 - 85 | 637 - 833 | 30 min |

| 0.6 | |||||

| 0.65 | |||||

| 0.7 | |||||

| 0.75 | |||||

| 0.8 | |||||

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Mr.Shi

Phone: +8613439184550

E-mail: haijinshian@gmail.com

Whatsapp:008613439184550

Add: CN , Hebei , Hengshui, , South Of 100 Meters Westbound Road At The Intersection Of Siwang Street And Beixin Avenue